Earthship

For those not familiar with this term, it was popularized by Micheal Reynolds to describe his design for an earth sheltered dwelling which makes extensive use of rubber tires filled with rammed earth.

Liquid Level Monitor

Project Overview

An integrated system for monitoring the volume of fluid contained in each of several irregularly shaped holding tanks aboard a marine vessel, the M/V Alaskan Legend.

Tasks Performed

Survey of current commercial offerings and applicable technology in the marketplace

Turnkey solution designed primarily for petroleum industry tank farms deemed inapplicable due to inability to tailor response for arbitrary tank shape.

Cost / performance comparison of available hardware to avoid overbuilding.

Sensor choice driven by concern for ease of installation and service without draining the tank.

System design and CAD model

Power budgeting to minimize the need for additional supply.

3D Enclosure design to ensure adequate space for hardware, while minimizing overall dimensions.

Specification and procurement of required hardware

Sensor calibration and installation

Addition of a calculated resistance to ensure that input falls within required range of 4-20 mA, while maximizing sensor resolution.

Enclosure assembly and packaging

Machining operations to accommodate controls, gauges, graphics panel.

Associated wiring and conduit.

Tank geometry analysis and characterization

Digitization of existing hard copy blueprints to obtain tank geometries.

Correlation of fluid level / volume behavior according to piecewise polynomial functions.

Software authoring

Ladder logic programming.

Sensor input interpretation and conditional response.

Graphical user interface and menu control.

System Commissioning & Troubleshooting

Correspondence and collaboration with hardware manufacturer technical support.

System response verification.

Ongoing client support and followup.

Mountainside Gardens

Construction and development of a small retail store. http://www.mountainsidegardens.com/

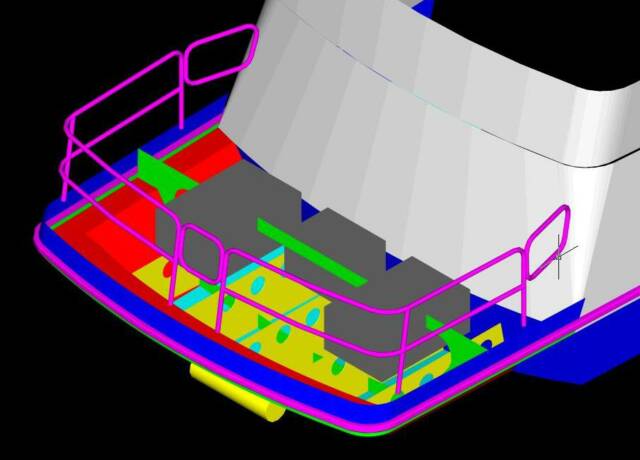

M/V Alaskan Legend

Maintenance, repairs, and modifications on a 76' aluminum motor vessel. You can link to an external page to learn more about this luxury charter yacht here.

Ehben Eliot